Deciding between screen printing and DTF for your apparel can be puzzling. Traditional screen printing and direct-to-film (DTF) are reshaping the textile industry’s landscape. Our guide dives into each method, helping you choose the perfect print path for your project.

Key Takeaways

- Screen printing uses a mesh to apply ink onto garments. It’s perfect for large orders and vibrant, durable designs with special effects like glitter.

- DTF (direct-to-film) printing is suitable for small, detailed jobs and works on many fabric types. It’s quicker and lower in waste than screen printing.

- Compare costs: DTF is more affordable for small orders, while screen printing saves money on larger runs thanks to lower costs per piece.

Understanding Screen Printing

Let’s talk about screen printing, the time-honored method where art meets textiles in a dance of pigments and mesh. It’s an intricate process that transforms a simple stencil into wearable masterpieces. It uses pressure, precision, and the human touch to bring designs to life on your favorite apparel.

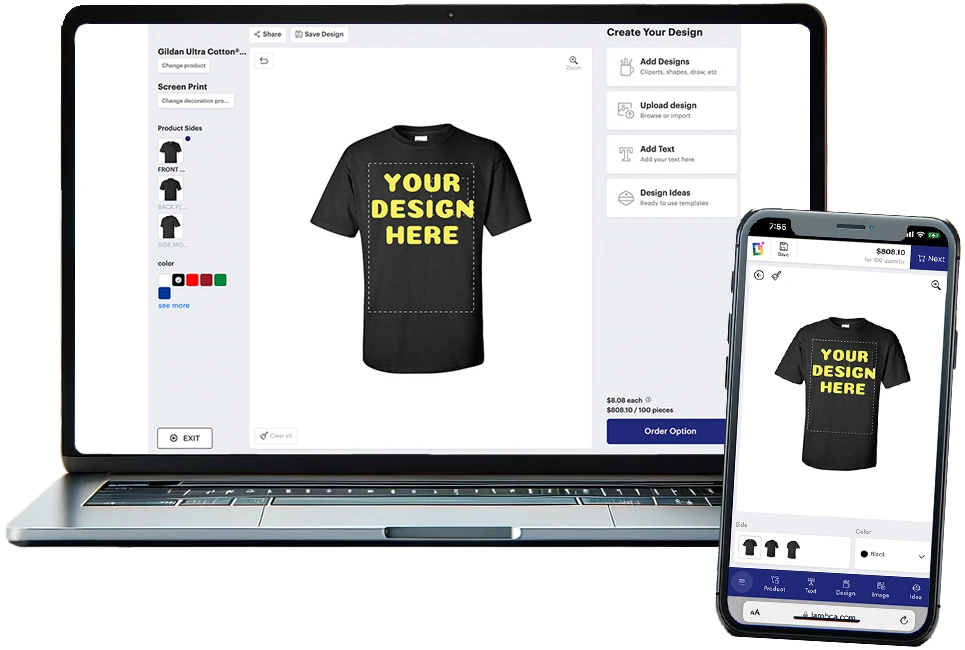

DESIGN YOUR OWN APPAREL

Overview of the Screen Printing Method

Screen printing is a popular method for creating designs on garments. It involves pushing ink through a mesh screen onto the shirt. Each color in your design requires its screen so that the process can handle multiple colors.

The ink is then cured with heat to create a durable and vibrant print.

This method has been around for ages, and it’s excellent for big jobs like sports team uniforms or family reunion shirts. Screen printers use squeegees to apply consistent pressure across the stencil, which sits atop the garment.

They make sure every inch of your design transfers perfectly. Proper equipment like presses and dryers lets you get high-quality prints that last long on any fabric type.

Benefits of Traditional Screen Printing

Screen printing stands out as a top choice for quality and durability. It allows you to create stunning designs on various fabrics, including polyester, silk, and cotton blends.

- Special Effects: You can achieve unique effects like luminous or glitter prints that sparkle and shine. Screen printing also offers crackle and foam effects for an extra touch of creativity.

- Vibrant Colors: Dark fabrics come alive with bright colors through this method. The ink layers build up a rich vibrancy that’s hard to match.

- Texture and Feel: Screen printed garments have a distinct hand feel that many customers love. This texture adds a premium quality to your clothing items.

- Durability: Prints are long-lasting and hold up well after multiple washes. Your design stays put without fading away quickly.

- Color Matching: With screen printing, you can match specific colors using Pantone codes. This precision is crucial for brands with signature shades.

- Fabric Versatility: Screen printing works on various materials, Whether nylon or a cozy cotton blend. You’re not limited in your fabric choices.

-

Hanes Beefy-T® T-Shirt$5.10 – $9.04

Hanes Beefy-T® T-Shirt$5.10 – $9.04 -

American Apparel Fine Jersey Tee$4.55 – $7.54

American Apparel Fine Jersey Tee$4.55 – $7.54 -

American Apparel CVC Tee$4.67 – $7.19

American Apparel CVC Tee$4.67 – $7.19 -

American Apparel Heavyweight Cotton Long Sleeve Tee$5.88 – $13.16

American Apparel Heavyweight Cotton Long Sleeve Tee$5.88 – $13.16

DTF Printing: An Introduction

Dive into the world of direct-to-film printing—often called DTF—a digital print technology that’s shaking up the industry. The machine can lay down vibrant designs onto a particular film. It’s quickly becoming the favorite of custom apparel decorators. They seek flexibility and precision.

Understanding DTF Printing

DTF printing is taking the textile industry by storm. It’s a game-changer for those who want to print vibrant designs on difficult fabrics. A DTF printer lays down a precise image in CMYK color onto a particular film.

Then, an adhesive powder is applied, and the print is pressed onto your t-shirt or other garments with a heat press. This method shines for small orders where setup time matters.

You won’t need separate screens for each color. DTF is cost-effective and less time-consuming than traditional screen printing. The results are impressive: crisp images with rich colors that pop! And since it’s suitable for on-demand jobs, you get precisely what you need without the waste.

Pros of DTF Printing

DTF printing, also known as Direct-to-Film printing, opens up a world of possibilities in textile decoration. Now, learn about the benefits this method offers.

- Detailed designs: DTF allows you to easily print intricate patterns and fine lines. You can create sharp images that might be too complex for screen printing.

- Colorful outcomes: Expect vibrant prints, even on dark fabrics. With DTF, your designs shine bright with a wide color gamut, including cyan and magenta.

- Versatility: It works on many fabric types—cotton, linen, polyester, denim, or canvas. This makes DTF transfers a good choice for various products.

- Small or large batches: DTF is cost-effective for both short and long print runs, whether it’s a single item or a big order.

- No need for screens: Skip the emulsion and screens used in traditional methods. This saves time and space in your workspace.

- Eco-friendly option: Less waste means it’s kinder to the environment. Some inks used for DTF are also more eco-friendly than typical screen-printing inks.

- DTF is easier to learn than mastering emulsion and substrates with screen printing. If you want to start decorating apparel with prints, learning DTF is straightforward.

WE HELP YOU MAKE AMAZING CUSTOM PRINTED TEES & APPAREL!

CUSTOM IS COMPLICATED

WE MAKE IT EZ

Let our dedicated team help guide you! Click below to send us basic information to get your order started!

Comparing DTF and Screen Printing

Let’s discuss the face-off between two popular decoration methods: DTF and screen printing. Each boasts unique advantages and disadvantages. We will soon provide a detailed comparison of these techniques. It will cover achieving a perfect gradient and considering cost-effectiveness for your project.

Quality of Print

DTF and screen printing both deliver unique qualities in print. Screen prints stand out on dark or colored fabrics, making bold statements with rich textures. The ink passes through a mesh screen, creating vibrant designs that pop.

Artists often choose this method for its spot color accuracy—it’s perfect for t-shirts that need to last.

On the other hand, DTF shines on light-colored materials and is known for its high-quality finish. This technique uses a printer to lay down colors before they get transferred onto the fabric.

It excels at gradient color printing, giving life to complex images with subtle shades and tones. DTF might be your go-to choice if you want your prints to look sharp and detailed.

Durability

Screen printing wins for durability. The ink lays on the fabric, creating a solid bond that can last years. Wash after wash; screen-printed designs stay bright and don’t peel.

DTF prints, while vibrant and precise, can show wear sooner. They need more care to keep looking good over time. Consider how long you want your print to last before choosing a method.

Cost Implications

DTF vs screen printing affect your wallet differently. With DTF, you’ll need less equipment to start. This makes it more affordable for small orders or unique designs.

The initial setup is cheaper as well.

Screen printing can seem pricey at first because of all the gear needed. Yet, if you’re planning big print runs, it becomes more affordable per piece. Keep in mind that larger volumes help lower overall costs with this method.

Think about what works best for how much you want to spend before choosing a technique.

Conclusion: DTF vs Screen Printing

You’ve got the scoop on screen printing and DTF now. Both methods shine in their ways, depending on what you’re after. Think about quality, durability, and costs before choosing your path.

Pick the method that fits your needs, whether a small project or a big run. Remember – in the world of printing on textiles, one size doesn’t fit all!

FAQs

Q: What is the difference between DTF printing vs Screen Printing?

A: Screen printing involves the use of a screen to transfer ink onto a substrate, while DTF (Direct to Film) printing involves printing onto a special film which is then heat pressed onto the substrate.

Q: Which printing method is better for high-quality prints with sharp details?

A: DTF printing is often preferred for high-quality prints with sharp details, as it allows for intricate designs to be transferred onto various substrates with precision.

Q: Can I use any artwork when using these techniques?

Vector artwork rocks for both methods. It has clean lines and scalability. Think logos or clipart that maintain clarity no matter the size. Raster images? They work, too, but require high resolution to keep every detail sharp!

Q: What are some popular printing methods in 2024?

A: In 2024, both screen printing and DTF printing are popular choices for businesses looking to create high-quality prints with vibrant colors and fine details.

Q: How does using a squeegee impact the printing process?

A: The squeegee is an essential tool in screen printing, as it is used to evenly force the ink to pass through the screen and onto the printing surface, ensuring a consistent and high-quality print.