Have you ever found yourself wrestling with the challenge of transferring your unique design onto a t-shirt or poster?

Trust us. We can relate to those screen printing battles. They turn simple ideas into tangible works of art.

Our guide is crafted to walk you through how does screen printing work. You’ll start by prepping mesh screens. Then, you’ll witness your ink-cured masterpieces come alive.

Let’s roll up our sleeves and unravel the mysteries of this creative process together!

Key Takeaways

- Screen printing is a method that involves pushing ink through a mesh screen onto materials like fabric, paper, wood, glass, and metal.

- Each color in a design needs its own screen for printing, making the process great for creating vibrant and long-lasting artwork.

- The process includes designing on acetate film. Then, exposing screens with light-sensitive emulsion to create screens. Next, add color using squeegees. Finally, heat-curing the print for durability.

- Various screen printing techniques include spot color for bold graphics. The simulated process is for detailed images. Halftone creates shades with one color. Grayscale is for classic looks.

- Screen printing equipment, such as automatic presses, film printers, and CTS makers, is crucial. Exposure units and belt dryers are also crucial for efficiency and quality.

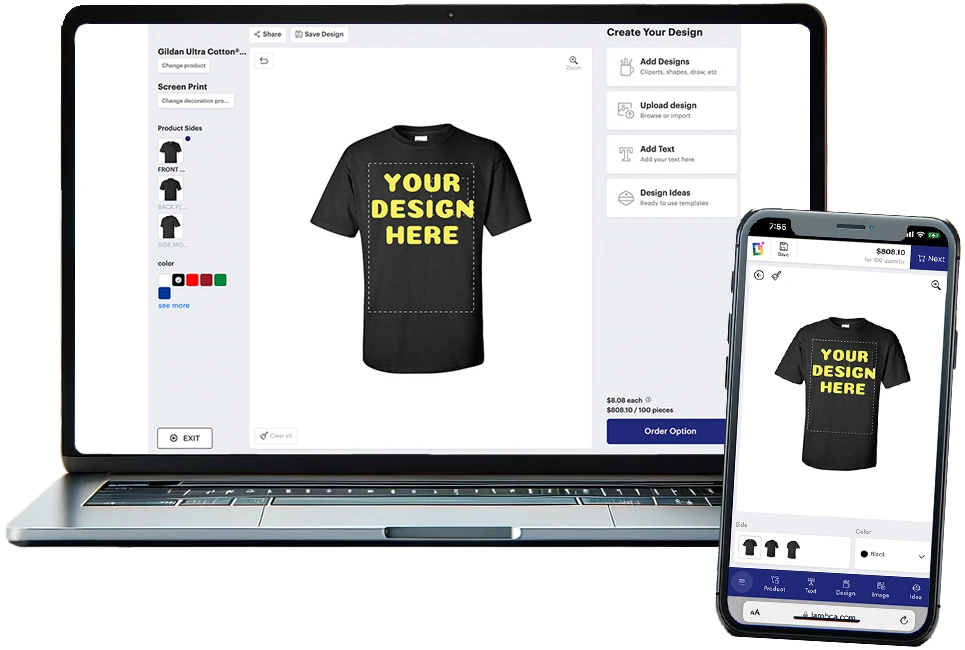

DESIGN YOUR OWN APPAREL

What is Silk Screen Printing?

How does screen printing work? We’ve come a long way from the early days of screen printing’s origins. Today, it is an influential method artists and businesses use to share their visuals with the world.

Screen printing pushes ink through a mesh screen to transfer an image onto fabric or paper. This age-old technique is also known as silk screening or serigraphy. It involves creating stencils, called screens, and applying layers of ink on the printing surface.

Each color in the design requires a separate screen. This makes the process excellent for vibrant artworks that last longer than those produced by digital printing alone.

It’s not just for t-shirts or posters; this versatile method works on various materials, including glass, wood, and metal! We embrace this craft because it produces unique looks you can’t get with other kinds of printing – sharp details and rich textures that stand out.

We use screen printing to make every impression count. Whether working on custom clothing or eye-catching signs.

The Screen Printing Process for T-Shirts

Diving into “How Does Screen Printing Work?”, we peel back the layers of this time-honored craft. It’s a meticulous dance between art and science. Precision meets creativity to transform a simple design into a wearable masterpiece.

Design Creation

We start our screen printing journey with a clear vision–your design must shine. First, we craft the image or text you want to display onto a transparent acetate film.

This film will lay the groundwork for creating an accurate screen, also known as a stencil.

Picking the proper emulsion is crucial; it’s like choosing paint for a masterpiece. We match the emulsion perfectly with your project’s needs. Three main types are available, each tailored for different effects and fabric types.

Exposing the Screen

Let’s talk about exposing the screen, a vital step in screen printing. After we printed our design onto a transparent acetate film, we laid this film on top of our mesh screen. This screen has been coated with a light-sensitive emulsion.

We shine bright light over it, hardening the emulsion that isn’t covered by the design.

Areas blocked by the design stay soft because they aren’t exposed to light. Later, we wash off these soft parts with water. What’s left is a clear stencil of your design on the mesh screen.

This stencil will let us push ink through and imprint it onto your chosen product—exciting stuff! With each careful step, we’re getting closer to bringing your custom creation to life.

WE HELP YOU MAKE AMAZING CUSTOM PRINTED TEES & APPAREL!

CUSTOM IS COMPLICATED

WE MAKE IT EZ

Let our dedicated team help guide you! Click below to send us basic information to get your order started!

Screen Creation

We took our design and chose a mesh screen to match it. The finer the detail in the design, the higher the mesh count we’ll need. Once we have our perfect mesh screen, we coat it with a light-reactive emulsion.

This substance will harden where light hits it, which is critical for our next step.

Now comes, exposing the screen. We lay the acetate sheet with our design onto the emulsion-coated mesh and expose it to bright light. The areas covered by our design stay soft while everything else hardens up solidly.

After exposure, we wash off those soft parts under water. This leaves clear open areas in the emulsion that will let ink pass through. This is how we create your stencil!

Printing the Design

Let’s get to the fun part – printing the design. We place our screen onto the printing board, right over the fabric or garment. It’s go-time! We pour ink on top of the screen and use a squeegee to push it across, ensuring we cover every inch with smooth, even strokes.

This only presses the paint through the mesh screen where our design allows it.

Carefully lifting off the screen reveals a masterpiece in progress! The ink sits perfectly on our chosen surface, thanks to precision work earlier in exposing and creating that sharp stencil.

Peek underneath – there it is, your vibrant design transferred onto fabric like magic. Each color might require its screen, but trust us, it’s worth that extra touch for a look that pops! Now, let’s move these beauties into curing because they’re not done yet; they must be heat-set before they can truly shine.

Heat Curing & Finishing

We take great care during the heat curing and finishing steps of screen printing. After carefully placing our images on the fabric or surface, it’s time to ensure those vibrant colors stay put.

Enter the conveyor dryer – a trusty machine that precisely dries and cures the ink. It works like magic, ensuring each print can withstand washes without losing shine.

We use flash curing between layers for specific projects, especially spot color screen printing. This neat trick partially sets the wet paint. We can layer more colors on top without smudging or bleeding. This is a real game-changer for detailed designs!

Our final touch might include a heat press to add durability and longevity to your printed items.

Different Types of Screen Printing

Screen printing offers a kaleidoscope of techniques. Each has unique charm and specific uses. We can bring our designs to life on many surfaces. You can capture crisp lines with spot color. You can also achieve intricate gradients through halftone printing.

There are creative ways to do this. Let’s dive into these methods. Let’s understand how they transform simple designs into vibrant expressions.

Spot Colour Screen Printing

We love the simplicity and power of spot color screen printing. This method is a favorite for its vibrant results and efficient process. We start by creating a stencil on a screen and press ink onto your chosen surface.

Each color gets its screen, ensuring crisp edges and bold colors that pop.

Let’s talk about how this benefits you as a customer. You’ll get products with eye-catching designs that last a long time – think shirts, bags, posters, and more! Spot color printing makes sure each hue stands out exactly how it should.

Plus, it’s cost-effective for both small and large orders. With us using only the necessary colors needed to bring your design to life, you save money while still getting high-quality prints.

Simulated Process Printing

Simulated process printing is our go-to method for bringing photorealistic images to life on your tees. This technique cleverly mixes spot color and four-color processes. Imagine capturing the complexity of a photograph or a detailed graphic in vibrant, eye-catching detail. That’s what this printing process can achieve.

Whether you want to print lifelike faces or scenic landscapes, we have the tools and expertise to deliver stunning results.

Our team excels at creating prints that pop with depth and dimension. We layer colors precisely, allowing us to reproduce intricate designs with clarity that turns heads.

Trust us: Simulated process printing makes your merchandise look amazing! Whether setting up a booth at an art fair or stocking up your online store, our printed products will help showcase the quality you stand for.

Halftone Printing

We use halftone printing to make awesome multi-color designs with just one ink color. It’s a smart way to save money while getting those cool shades in your printed design. Imagine using tiny dots that get bigger or smaller to create light and dark areas—this is how we make different tones from one color.

This technique lets us produce images full of detail without needing lots of different colored inks.

Our team loves halftone printing. It highlights intricate details and shading in your screen-printed items. Each dot works together to give the illusion of depth, making your design pop! Moving on, let’s explore another interesting method: grayscale printing.

Grayscale Printing

Grayscale printing lets us turn colorful images into different shades of gray. It’s a way to save money while still getting detailed designs onto fabric. This method is perfect for classic black-and-white looks that always stay in style.

Our approach ensures the final product has the crisp, clear imprint you want.

We start by choosing a mesh screen that suits your design. Then we coat it with an emulsion that will only harden where there’s no design, creating the stencil needed to push ink through onto your shirt or tote bag.

Each pull of the squeegee floods the entire screen length with just enough ink to capture every fine detail without smudging or bleeding. This gives you an impressive result every time.

Screen Printing Equipment

Ensuring every detail of your vision comes to life on fabric or paper demands the right tools. We’re talking about a lineup of specialized equipment. It’s designed to handle the intricacies and creativity of screen printing.

Sophisticated automatic presses boost efficiency. Precise exposure units are integral for stencil perfection. Each piece plays a role in transforming a simple idea into a tactile masterpiece.

Automatic printing press

You might need to print on different surfaces, and that’s where an automatic printing press shines. It speeds up the screen printing process, ensuring every print is consistent.

Think of it like a pro athlete: fast, reliable, and ready for heavy-duty action. Each color gets its screen, allowing complex designs to come to life quickly.

Imagine having a machine that tirelessly works precisely. This is what our automatic printing presses do for your projects. They’re the workhorses in screen printing equipment. They push ink onto surfaces swiftly and uniformly.

With these presses, Ynvisible takes roll-to-roll screen printing to new heights. They churn out smart displays cost-effectively at large volumes.

Film printer / CTS screen maker

We start our journey into screen printing by creating a clean, crisp design. We use a state-of-the-art film printer or computer-to-screen (CTS) maker to make this happen. Think of it as laying the foundation for a masterpiece—this step is crucial.

First, your unique design gets printed onto transparent acetate film. This precise image will transfer to the screen and become our stencil.

Using the CTS system cuts down on time and boosts accuracy. It’s like having an expert artist draw directly onto the screen without any room for error. Once we’ve got that perfect imprint of your design, we’re ready to bring it to life through silk screen printing.

The equipment ensures every detail of your artwork is captured just right—no smudges or missing parts! Efficiency matters to us. This technology helps speed up the process while maintaining top-notch quality.

Screen exposure unit

After creating the design with a film printer or CTS screen maker, we use a screen exposure unit to bring that design to life on our screens. It’s like magic for screen printing! The exposure unit shines bright light over stencil-covered screens. This ensures only specific areas let ink through.

We rely on different emulsions in this step. They react to the light and harden around our designs. This creates precise stencils on our screens ready for printing. It’s essential for clear, sharp images on your shirts, signs, or stickers.

Consider it setting the stage for vibrant prints that last long and look stunning!

Belt dryer

Once our screens are prepped and ready, it’s time to bring in the belt dryer. This powerhouse plays a vital role in screen printing by ensuring our designs are dried quickly and evenly.

We rely on these dryers as they come tailor-made for different project sizes. They’re customizable with variable speeds and temperatures, so we can adjust them perfectly to cure ink on any print job.

In our shop, a belt dryer works hand-in-hand with the rest of our equipment. It allows us to increase how much we produce while keeping labor costs down. We always keep up with cleaning and maintaining this essential tool so your prints turn out crisp, clear, and long-lasting every time.

With this machine humming along in the background, you can trust that each item coming off the line is ready for whatever comes next. It could be hitting store shelves or going straight into your hands.

Benefits Of Screen Printing

Discover why screen printing reigns supreme for custom designs. Its unmatched versatility, enduring durability, and the bold vibrancy of its inks are just the beginning. Join us to uncover all the compelling advantages this method offers for your next project.

Versatility

Screen printing amazes us with its flexibility. We can print on fabric, wood, glass, and even leather. Imagine turning a bland t-shirt into vibrant wearable art. Or transforming simple wood into eye-catching signage.

This technique adapts to different materials, allowing creativity to flourish in multiple industries.

We love screen printing for products like jackets and hoodies because it works so well on different surfaces. It’s more than just putting ink onto an item; it’s about crafting a lasting message—a printed design that endures wash after wash.

Whether you need something chic for your office or casual wear for the streets, we’ve got you covered using this versatile method.

Durability

Our screen printing stands the test of time. It’s tough enough for clothing that gets washed a lot and signs that face all kinds of weather. We’re talking about a printing method that keeps designs looking sharp and colors bright, even after heavy use.

Think medical devices, decals, stickers, and labels—all need to last. That’s why we rely on screen printing for durable results. It handles wear and tear like a champ, making customers happy with products that have looked great for years.

Vibrancy of ink colors

We love how screen printing brings designs to life with stunning colors. Our inks shine brightly, making every image pop off the material. Whether you’re after bold or subtle tones, we have the rainbow at our fingertips.

Imagine your logo on a t-shirt, glowing with color that grabs everyone’s attention. That’s what we do.

The right colors can make or break a design. We use vibrant inks because they last longer and stay brilliant after washing. This isn’t just about looks; it’s innovative business, too! Colors that stand out mean your message gets seen—even from across the room.

Trust us to splash your world with color that counts!

Cost-effective

Screen printing stands out as a budget-friendly choice, especially when you’re looking to place bulk orders. It’s far less expensive per unit than digital printing for large quantities.

We use this process to print on various surfaces, which saves you money without compromising quality. You’ll find that the inks used are also more affordable and last longer.

Automating screen printing enhances its cost advantage even further when producing high volumes. Complex manual labor is reduced, cutting down on costs and time. With us, you reap the benefits of these savings while still getting top-notch printed products ready for your use or sale.

Conclusion: How Does Screen Printing Work

We’ve walked through the fascinating world of screen printing together. It’s clear why this craft has stood the test of time, offering a blend of tradition and innovation. Whether you’re making custom tees or unique posters, each step takes you closer to a masterpiece.

Screen printing turns your visions into vivid reality with every squeegee pull and flash cure. Let’s get our creative juices flowing—our next project awaits!

FAQs

Q: What exactly is screen printing?

Screen printing, or silkscreen printing, uses a mesh screen to transfer ink onto a surface. During the process, parts of the screen are blocked off to create a stencil for the design.

Q: Is there more than one way to do screen printing?

Yes! You can use manual methods or an automatic rotary carousel printer for different projects. The choice depends on what you’re creating – from custom fabric prints to unique posters.

Q: Can I use any ink for the process?

Not reasonably – you’ll need special paints for the fabric or material you use. Screen printers carefully push the ink through the stencil onto your product so that only your design appears.

Q: Why choose screen printing over digital options?

Screen printing offers vibrant colors and durability, especially when compared to digital prints. Each piece has its unique touch because every layer of color is applied separately.

Q: What are the steps involved in the screen printing process?

The screen printing process typically involves creating or preparing the design on the screen. Then, coating the screen with the design with ink. Finally, using a squeegee to press the colors through the screen onto the material.

Q: Is screen printing similar to digital printing?

Screen printing is a distinct printing method that uses a stencil and screen to transfer ink. Digital printing involves directly printing an image onto a surface using a digital printer.

Q: What equipment is needed for screen printing?

The essential equipment for screen printing includes a screen, exposure unit, ink, a squeegee, and a printing board to hold the printed material.

Q: How does silk screen printing differ from other screen printing methods?

Silk screening refers to using silk mesh as the screen, whereas other methods may use different types of mesh. The process of transferring ink through the screen remains the same.

Q: What is duotone printing and its significance in screen printing?

Duotone printing refers to using two ink colors to create a halftone image. This method can add depth and dimension to a design when applied through screen printing.